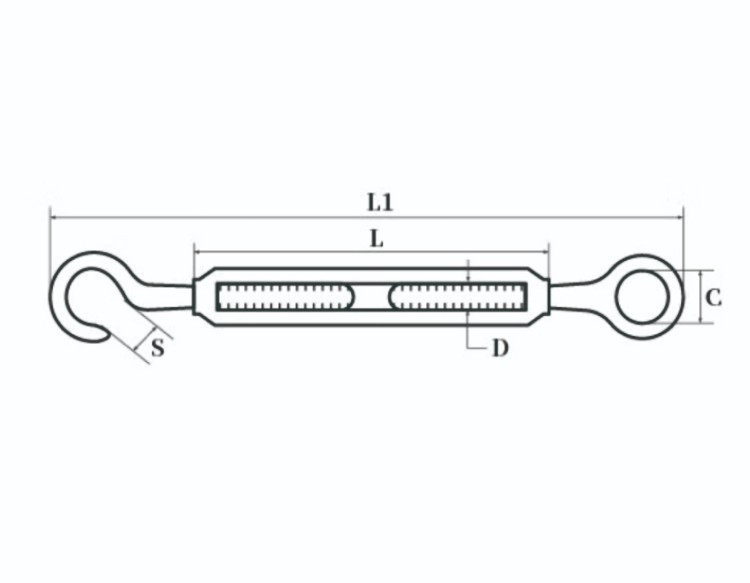

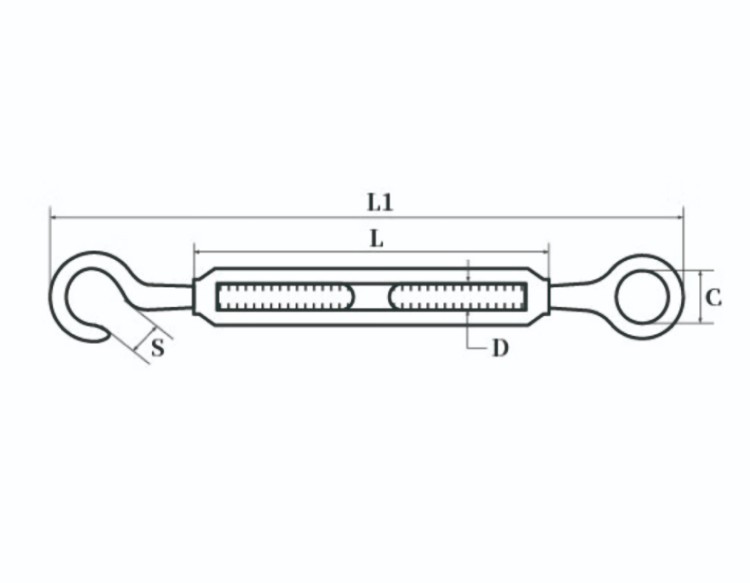

| Specification | C | D | S | L | L1 | Adjustable distance(mm) |

| M4 | 9.3 | 5 | 7.5 | 60 | 107 | 39 |

| M5 | 9.7 | 5 | 7.5 | 73 | 124 | 59 |

| M6 | 10.5 | 6 | 9.6 | 91 | 150 | 64 |

| M8 | 12.5 | 8 | 9.6 | 122.8 | 192 | 96 |

| M10 | 15 | 10 | 11.3 | 150 | 240 | 115 |

| M12 | 17.5 | 12 | 18.4 | 197 | 303 | 163 |

| M16 | 26.5 | 16 | 21.8 | 248 | 385 | 193 |

| M20 | 30.1 | 20 | 22.1 | 299 | 465 | 232 |

| M24 | 24.9 | 24 | 23.7 | 356 | 531 | 269 |

Here are some key features and uses of a turnbuckle:

1.Design: It normally consists of two threaded eye bolts, one screwed into each end of a small metal frame, one with a conventional right-hand thread and the other with a left-hand thread. The tension can be adjusted by rotating the frame, which causes both eye bolts to be screwed in or out simultaneously, without twisting the eye bolts or attached cables.

2.Usage: Turnbuckles are most commonly used in applications which require a great deal of tension; they can range in mass from about 10 grams for thin cable used in a garden fence, to tonnes for structural elements in buildings and suspension bridges.

3.Applications: They have been used in various fields such as aircraft construction, shipping, sports, entertainment industry, pipe systems, and orthopaedics.