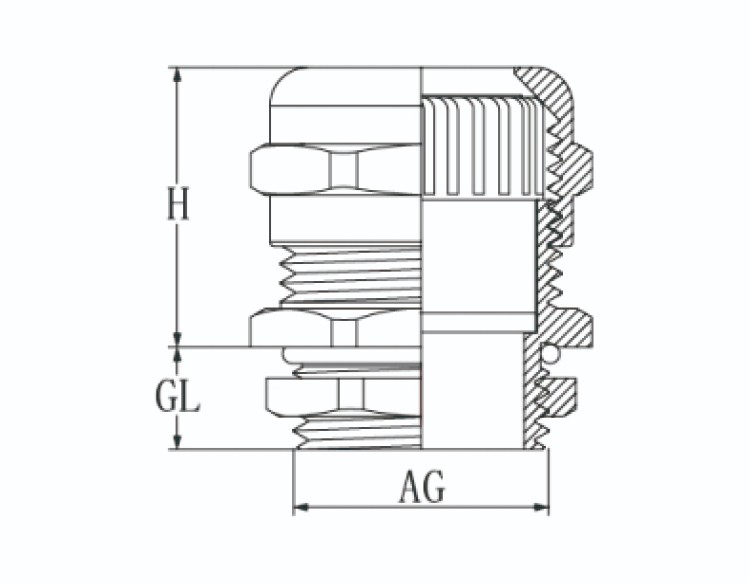

| Item | Range | Thread Length | Thread O.D. | Joint Length | Spanner size | Code |

| M10×1 | 2-5 | 6.5 | 10 | 17 | 14 | HX-NPM10-5 |

| M12×1.5 | 2-5 | 6.5 | 12 | 17 | 14 | HX-NPM12-5 |

| M14×1.5 | 3-6 | 8 | 14 | 18 | 17 | HX-NPM14-6 |

| M16×1.5 | 3-6 | 8 | 16 | 19 | 18 | HX-NPM16-6 |

| M18×1.5 | 3-7 | 8 | 18 | 20 | 20 | HX-NPM18-7 |

| M20×1.5 | 5-10 | 8 | 20 | 21 | 22 | HX-NPM20-10 |

| M22×1.5 | 8-12 | 8 | 22 | 22 | 24 | HX-NPM22-12 |

| M24×1.5 | 8-12 | 9 | 24 | 22 | 24/27 | HX-NPM24-12 |

| M25×1.5 | 8-12 | 9 | 25 | 22 | 24/27 | HX-NPM25-12 |

| M27×1.5 | 12-16 | 9 | 27 | 27 | 30 | HX-NPM27-16 |

| M30×2 | 12-16 | 9 | 30 | 27 | 30/32 | HX-NPM30-16 |

| M32×1.5 | 13-18 | 10 | 32 | 29 | 35 | HX-NPM32-18 |

| M33×2 | 14-20 | 10 | 33 | 29 | 35/36 | HX-NPM33-20 |

| M36×1.5 | 13-18 | 10 | 36 | 31 | 40 | HX-NPM36-18 |

| M36×1.5 | 15-22 | 10 | 36 | 31 | 40 | HX-NPM36-22 |

| M40×1.5 | 18-25 | 11 | 40 | 31 | 40/45 | HX-NPM40-25 |

| M47×1.5 | 23-30 | 11 | 47 | 37 | 50 | HX-NPM47-30 |

| M48×2 | 23-30 | 11 | 48 | 37 | 50/52 | HX-NPM48-30 |

| M50×1.5 | 30-35 | 13 | 50 | 37 | 57/55 | HX-NPM50-35 |

| M60×1.5 | 35-40 | 14 | 60 | 38 | 64 | HX-NPM60-40 |

| M63×1.5 | 35-40 | 14 | 63 | 38 | 64/68 | HX-NPM63-40 |

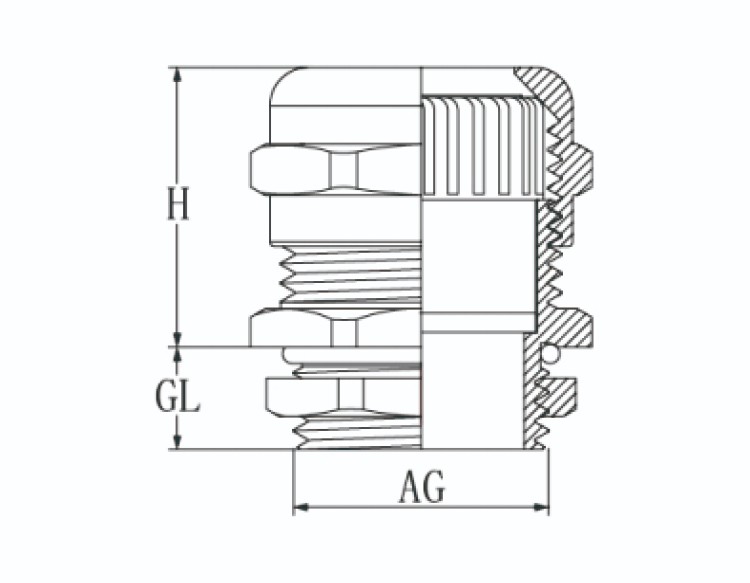

| Item | Range | Thread Length | Thread O.D. | Joint Length | Spanner size | Code |

| PG7 | 2-5 | 6.5 | 12.5 | 12.5-12.7 | 17 | HX-NPPG7-5 |

| PG7 | 3-6.5 | 6.5 | 12.5 | 12.5-12.7 | 17 | HX-NPPG7 |

| PG9 | 3-6.5 | 8 | 15.2 | 15.2-15.4 | 19 | HX-NPPG9-6.5 |

| PG9 | 4-8 | 8 | 15.2 | 15.2-15.4 | 19 | HX-NPPG9 |

| PG11 | 4-8 | 8 | 18.6 | 18.6-18.8 | 21 | HX-NPPG11-8 |

| PG11 | 5-10 | 8 | 18.6 | 18.6-18.8 | 21 | HX-NPPG11 |

| PG13.5 | 5-10 | 8 | 20.4 | 20.4-20.6 | 22 | HX-NPPG13.5-10 |

| PG13.5 | 6-12 | 8 | 20.4 | 20.4-20.6 | 22 | HX-NPPG13.5 |

| PG16 | 6-12 | 8 | 22.5 | 22.5-22.7 | 23 | HX-NPPG16-12 |

| PG16 | 10-14 | 8 | 22.5 | 22.5-22.7 | 23 | HX-NPPG16 |

| PG21 | 12-16 | 9 | 28.3 | 28.3-28.5 | 27 | HX-NPPG21-16 |

| PG21 | 13-18 | 9 | 28.3 | 28.3-28.5 | 27 | HX-NPPG21 |

| PG29 | 15-22 | 10 | 37 | 37.0-37.2 | 31 | HX-NPPG29-22 |

| PG29 | 18-25 | 10 | 37 | 37.0-37,2 | 31 | HX-NPPG29 |

| PG36 | 23-30 | 11 | 47 | 47.0-47.2 | 37 | HX-NPPG36-30 |

| PG36 | 25-33 | 11 | 47 | 47.0-47,2 | 37 | HX-NPPG36 |

| PG42 | 30-35 | 13 | 54 | 54.0-54.2 | 37 | HX-NPPG42-35 |

| PG42 | 32-38 | 13 | 54 | 54.0-54.2 | 37 | HX-NPPG42 |

| PG48 | 35-40 | 14 | 59.3 | 59.3-59.5 | 38 | HX-NPPG48-40 |

| PG48 | 37-44 | 14 | 59.3 | 59.3-59.5 | 38 | HX-NPPG48 |

1.Material:Metal Cable Glands are made of various metals, including steel, brass or aluminum for industrial usage.

2.Function:It provides strain relief and connects by a means suitable for the type and description of cable for which it is designed. This includes provision for making electrical connection to the armour or braid and lead or aluminium sheath of the cable, if any.

3.Application:

1)Cable glands are used throughout a number of industries in conjunction with cable and wiring used in electrical instrumentation and automation systems.

2)They are used on all types of electrical power, control, instrumentation, data and telecommunications cables.

3)They are used as a sealing and termination device to ensure that the characteristics of the enclosure which the cable enters can be maintained adequately.