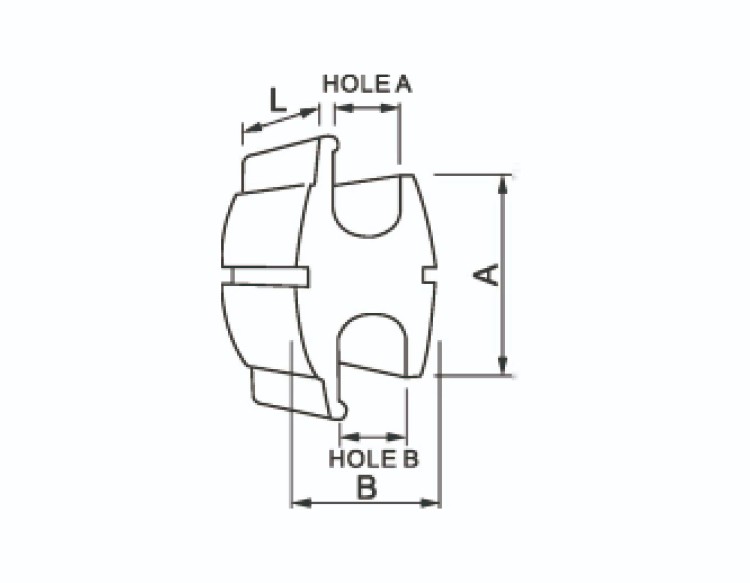

| Modle | Hole1 mm2 | Hole2 mm2 | Dimensions(mm) | ||

| A | B | L | |||

| CPTH35-35 | 16-35 | 16-35 | 17.5 | 23.8 | 38 |

| CPTH 35-70 | 16-35 | 35-70 | 17.8 | 26 | 46 |

| CPTH 70-70 | 35-70 | 35-70 | 20.6 | 30.5 | 47 |

| CPTH 120-120 | 70-120 | 70-120 | 22.7 | 36.5 | 52 |

| CPTH 70-150 | 35-150 | 70-150 | 23 | 34.5 | 70 |

| CPTH 150-150 | 70-150 | 70-150 | 25.4 | 39.5 | 70 |

| CPTH 70-240 | 35-70 | 120-240 | 28 | 42 | 90 |

| CPTH 150-247 | 70-150 | 120-240 | 32 | 46 | 90 |

| CPTH 240-240 | 120-240 | 120-240 | 32 | 52 | 90 |

| CPTH 300-300 | 150-300 | 150-300 | 32 | 52 | 100 |

Here are the key details:

1.Design: The H-shape tap connector features a universal and reversible design that separates the run and tap conductors, minimizing galvanic corrosion.

2.Application: It is suitable for a wide range of conductors.

3.Installation: The connector can be gripped in a tool and slipped over the line for easier installation.

4.Conductor Separation: Conductors are separated by the shape of the connector.

5.Features:

1)Bendable tabs secure both run and tap conductors, allowing the lineman's hands to work with the installation tool.

2)The massive aluminum design minimizes corrosion due to galvanic effects.

3)Each connector has multiple aluminum cable combination applications, providing flexibility in system design and installation.