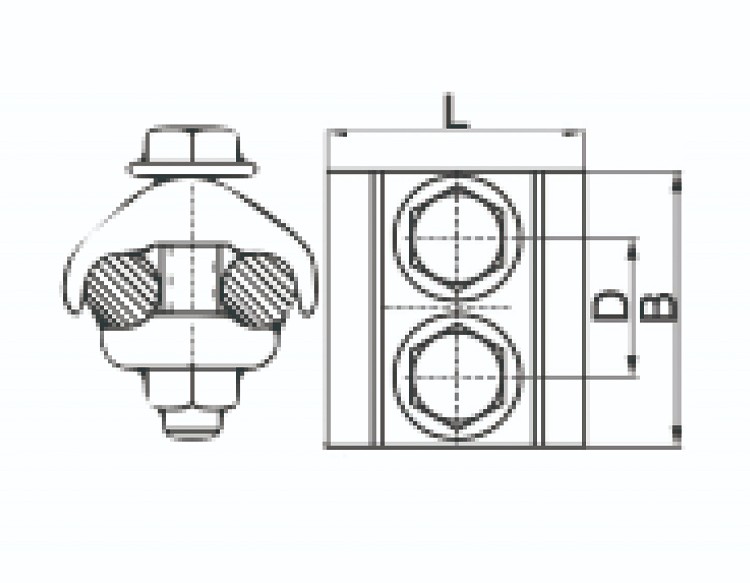

| Modle | Bolt Torque | Conductor Range mm2 | Dimensions mm O.D | No./Size of Bolts |

| CU6-70-2 | 20Nm | 6 to 70 | 2.7 to 10.5 | 2×M8 |

| CU16-95-2 | 20Nm | 16 to 95 | 5.1 to 12.5 | 2×M8 |

| CU16-150-2 | 30Nm | 16 to 150 | 5.1 to 15.7 | 2XM10 |

| CU150-240-2 | 40Nm | 150 to 240 | 15.7 to 20.3 | 2×M12 |

| CU300-400-3 | 40Nm | 300 to 400 | 22.6 to 26.7 | 3×M12 |

Here are some key features of Parallel Groove Clamps (CU-CU):

1.Material: These clamps are made from forged copper, ensuring a reliable connection between copper conductors.

2.Serrated Grooves: The clamps have serrated transverse grooves that maximize conductor contact area, enhancing electrical conductivity.

3.Bolts and Belleville Washers: Copper bolts are used, and belleville washers prevent thermal ratcheting under cyclic loads.