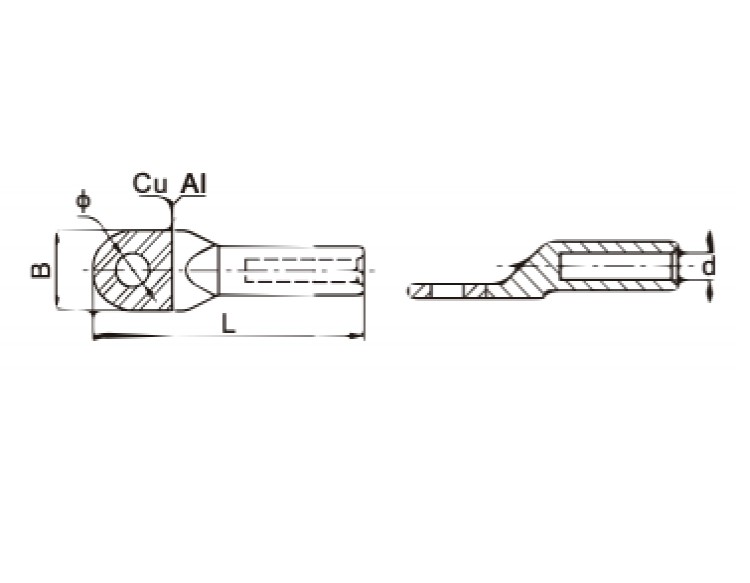

| Catalog No. | Dimensions(mm) | |||

| L | d | B | Φ | |

| DTL 10-6 | 62 | 4.8 | 13.5 | 6.5 |

| DTL 16-8 | 70 | 5.8 | 16 | 8.5 |

| DTL 25-8 | 75 | 7.2 | 17.5 | 8.5 |

| DTL35-10 | 85 | 8.5 | 20 | 10.5 |

| DTL50-10 | 90 | 9.7 | 23 | 10.5 |

| DTL70-12 | 102 | 11.5 | 26 | 12.5 |

| DTL95-12 | 112 | 13.5 | 28 | 12.5 |

| DTL120-14 | 120 | 15 | 31 | 14.5 |

| DTL150-14 | 125 | 16.5 | 35 | 14.5 |

| DTL185-16 | 133 | 18.5 | 37.5 | 17 |

| DTL240-16 | 140 | 21 | 40 | 17 |

| DTL300-18 | 160 | 23.5 | 44.5 | 18.5 |

| DTL400-20 | 170 | 27 | 50 | 21 |

| DTL500-20 | 225 | 29 | 60 | 21 |

Bimetal Lug-DTL series typically feature:

1.A copper eye for screwing non-tension connections, often used in humid areas.

2.An aluminum barrel filled with neutral grease and covered by a cap to prevent oxidation.

3.Friction welding for a strong, reliable connection.

4.High purity materials, usually with copper (Cu) content of at least 99.9% and aluminum (Al) content of at least 99.5%.

These lugs are designed to connect aluminum and copper conductors safely and efficiently, preventing galvanic corrosion.