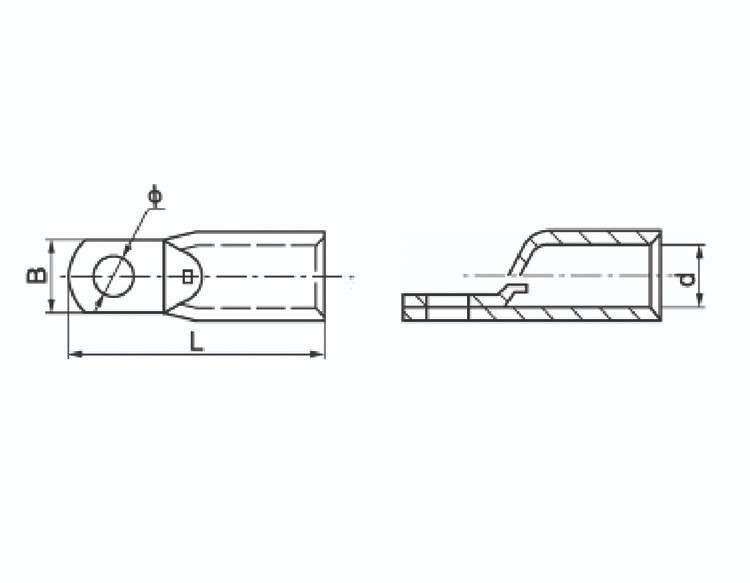

| Catalog No. | Dimensions(mm) | |||

| L | d | B | Φ | |

| TM10-5 | 27 | 4.3 | 9 | 5.3 |

| TM16-5 | 31 | 5.6 | 9 | 5.3 |

| TM25-5 | 35 | 7 | 9 | 5.3 |

| TM35-6 | 40.5 | 8.4 | 11.5 | 6.4 |

| TM50-8 | 45.5 | 9.5 | 12.8 | 8.4 |

| TM70-8 | 49 | 11.2 | 12.8 | 8.4 |

| TM95-8 | 54 | 13.5 | 15.5 | 8.4 |

| TM120-8 | 68 | 15.6 | 19 | 8.4 |

| TM120-10 | 68 | 15.6 | 19 | 10.5 |

| TM150-8 | 75 | 16.7 | 19 | 8.4 |

| TM150-10 | 75 | 16.7 | 19 | 10.5 |

| TM185-10 | 79 | 19 | 24.5 | 10.5 |

| TM240-10 | 86 | 21.1 | 29.8 | 10.5 |

| TM240-12 | 92 | 21.1 | 29.8 | 13.2 |

| TM240-16 | 100 | 21.1 | 29.8 | 17 |

| TM300-12 | 97 | 23.7 | 31 | 13.2 |

1.They often have an inspection window for visual confirmation of correct cable installation and an annealed copper barrel to maximize crimping properties.

2.The surface is usually Tin-plated to resist corrosive environments.