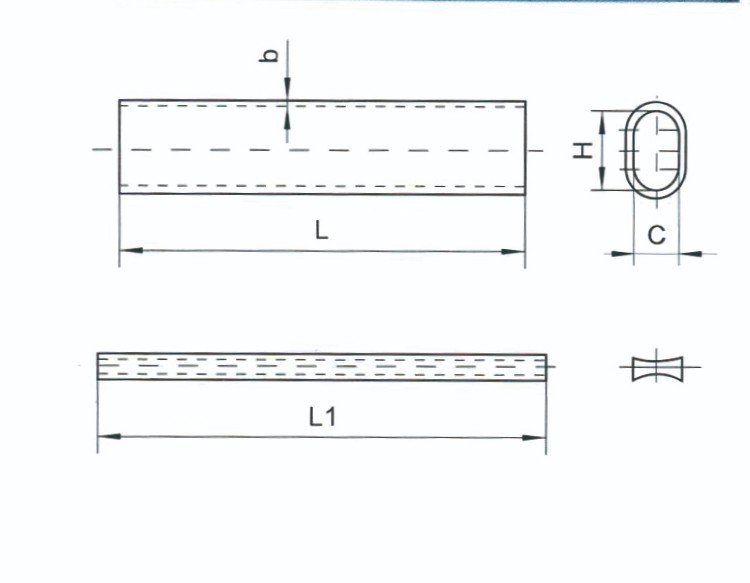

| Cataiog No. | Suitable Conductor | Main dimensions(mm) | Weight(KG) | |||

| D | d | L1 | L2 | |||

| JYT-35/6 | LGJ-35/6 | 16 | 9.5 | 60 | 65 | 0.41 |

| JYT-50/8 | LGJ-50/8 | 18 | 11 | 60 | 65 | 0.45 |

| JYT-70/10 | LGJ-70/10 | 22 | 13 | 70 | 65 | 0.54 |

| JYT-95/15 | LGJ-95/15 | 26 | 15 | 80 | 65 | 0.62 |

| JYT-120/7 | LGJ-120/7 | 26 | 16 | 80 | 85 | 0.6 |

| JYT-120/20 | LGJ-120/20 | 26 | 16.5 | 80 | 85 | 0.58 |

| JYT-150/8 | LGJ-150/8 | 30 | 17.5 | 90 | 85 | 0.84 |

| JYT-150/20 | LGJ-150/20 | 30 | 18 | 90 | 85 | 0.84 |

| JYT-150/25 | LGJ-150/25 | 30 | 18.5 | 90 | 85 | 0.84 |

| JYT-185/10 | LGJ-185/10 | 32 | 19.5 | 90 | 85 | 0.94 |

| JYT-185/25 | LGJ-185/25 | 32 | 20.5 | 90 | 85 | 0.9 |

| JYT-185/30 | LGJ-185/30 | 32 | 20.5 | 90 | 85 | 0.9 |

| JYT-210/10 | LGJ-210/10 | 34 | 20.5 | 100 | 85 | 1.18 |

| JYT-210/25 | LGJ-210/25 | 34 | 21.5 | 100 | 85 | 1.14 |

| JYT-210/35 | LGJ-210/35 | 34 | 22 | 100 | 85 | 1.1 |

| JYT-240/30 | LGJ-240/30 | 36 | 23 | 110 | 85 | 1.21 |

| JYT-240/40 | LGJ-240/40 | 36 | 23 | 100 | 85 | 1.21 |

| JYT-300/15 | LGJ-300/15 | 40 | 24.5 | 110 | 105 | 1.74 |

| JYT-300/25 | LGJ-300/25 | 40 | 25 | 110 | 105 | 1.74 |

| JYT-300/40 | LGJ-300/40 | 40 | 25.5 | 110 | 105 | 1.74 |

Here are some key features and details about these splicing sleeves:

1.Material: They are typically made of a high conductivity/high strength aluminum alloy outer tube and corrosion-resistant high strength galvanized steel hardware.

2.Design: These splicing sleeves often have a two-piece design, consisting of a steel inner sleeve and an aluminum outer sleeve. This design is intended to provide full tension on the ACSR conductor.

3.Installation: The installation of these splices involves an explosive overlap joint. This method uses a controlled explosion to create a high-quality joint, ensuring a secure and reliable connection.

4.Performance: They are designed to develop 95% or more of the conductor’s rated strength.

5.Standards: These splicing sleeves meet or exceed ANSI C119.4 specifications.