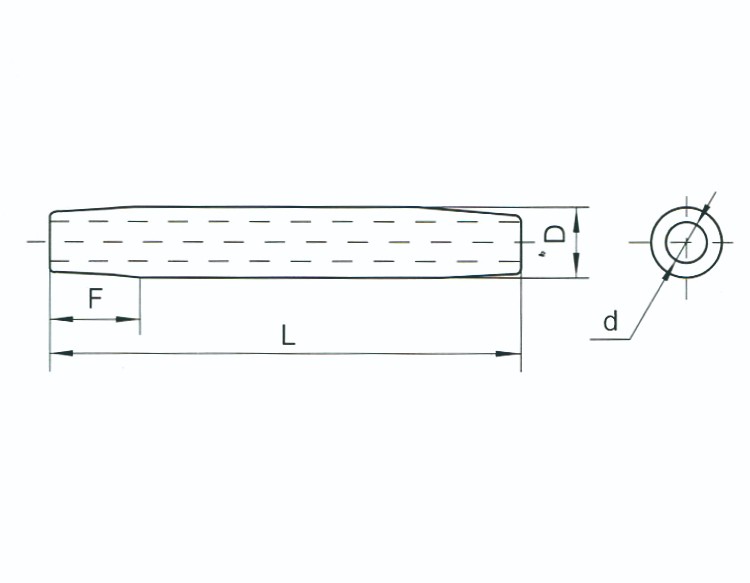

| Cataiog No. | Suitable Conductor | Main dimensions(mm) | Grip Strength (kN) | Weight(KG) | |||

| L | D | d | F | ||||

| JY-150L | LJ-150 | 280 | 30 | 17 | 20 | 22 | 0.36 |

| JY-185L | LJ-185 | 310 | 32 | 19 | 20 | 27 | 0.44 |

| JY-210L | LJ-210 | 330 | 34 | 20 | 20 | 31 | 0.6 |

| JY-240L | LJ-240 | 350 | 36 | 21.5 | 20 | 34 | 0.75 |

| JY-300L | LJ-300 | 390 | 40 | 24 | 25 | 45 | 0.95 |

| JY-400L | LJ-400 | 450 | 45 | 27.5 | 25 | 58 | 1.5 |

| JY-500L | LJ-500 | 510 | 52 | 30.5 | 30 | 73 | 2 |

| JY-630L | LJ-630 | 570 | 60 | 34 | 35 | 87 | 2.8 |

| JY-800L | LJ-800 | 650 | 65 | 38.5 | 40 | 110 | 4.8 |

| Cataiog No. | Suitable Conductor | Main dimensions(mm) | Weight(G) | ||

| L | D | d | |||

| XH-ClassA 10mm2 | LJ-10 | 60 | 9 | 5.5 | 7 |

| XH-ClassA 16mm2 | LJ-16 | 65 | 10 | 6.5 | 8 |

| XH-ClassA 25mm2 | LJ-25 | 70 | 12 | 7 | 15 |

| XH-ClassA 35mm2 | LJ-35 | 75 | 14 | 8.3 | 19 |

| XH-ClassA 50mm2 | LJ-50 | 80 | 16 | 10 | 27 |

| XH-ClassA 70mm2 | LJ-70 | 90 | 18 | 12 | 36 |

| XH-ClassA 95mm2 | LJ-95 | 95 | 21 | 14 | 52 |

| XH-ClassA 120mm2 | LJ-120 | 100 | 23 | 15 | 67 |

| XH-ClassA 150mm2 | LJ-150 | 115 | 25 | 17 | 78 |

| XH-ClassA 185mm2 | LJ-185 | 115 | 27 | 19 | 93 |

| XH-ClassA 240mm2 | LJ-240 | 120 | 30 | 21 | 122 |

| XH-ClassA 300mm2 | LJ-300 | 130 | 34 | 24 | 167 |

| XH-ClassA 400mm2 | LJ-400 | 150 | 37 | 27 | |

| XH-ClassA 500mm2 | LJ-500 | 170 | 40 | 30 | |

| Cataiog No. | Suitable Conductor | Main dimensions(mm) | Weight(G) | ||

| L | D | d | |||

| XH-ClassB 10mm2 | LJ-10 | 52 | 8 | 5 | 5.8 |

| XH-ClassB 16mm2 | LJ-16 | 59 | 9 | 6 | 6 |

| XH-ClassB 25mm2 | LJ-25 | 61 | 11 | 7.5 | 9 |

| XH-ClassB 35mm2 | LJ-35 | 65 | 12 | 8.5 | 11 |

| XH-ClassB 50mm2 | LJ-50 | 71 | 15 | 11 | 16.5 |

| XH-ClassB 70mm2 | LJ-70 | 81 | 17 | 12.4 | 24.2 |

| XH-ClassB 95mm2 | LJ-95 | 85 | 19 | 11 | 32 |

| XH-ClassB 120mm2 | LJ-120 | 91 | 21 | 15.6 | 41 |

| XH-ClassB 150mm2 | LJ-150 | 95 | 23 | 17.5 | 46 |

| XH-ClassB 185mm2 | LJ-185 | 102 | 25 | 19.4 | 57 |

| XH-ClassB 240mm2 | LJ-240 | 112 | 27 | 21 | 73 |

| XH-ClassB 300mm2 | LJ-300 | 124 | 32 | 24 | 123 |

Here are some key points about splicing sleeves:

1.Purpose:

1)Splicing sleeves are used to connect two or more wires or conductors together.

2)They provide mechanical strength, stability, and electrical continuity.

2.Types:

1)Compression Sleeves: These sleeves rely on compression (using tools or dies) to create a secure joint.

2)Overlap Joint Sleeves: These sleeves use an overlap joint method (e.g., explosive overlap) for connecting wires.

3)Swaging Sleeves: Used to create eye loops or stopping points on wire ropes.

4)Repair Sleeves: Specifically designed for repairing damaged conductors.

3.Materials:

1)Splicing sleeves can be made of materials like aluminum, steel, or other alloys.

2)The choice of material depends on the application, conductor type, and environmental conditions.

4.Installation:

1)Proper installation is crucial for their effectiveness.

2)Gauge tools are often used to ensure accurate pressing or compression.