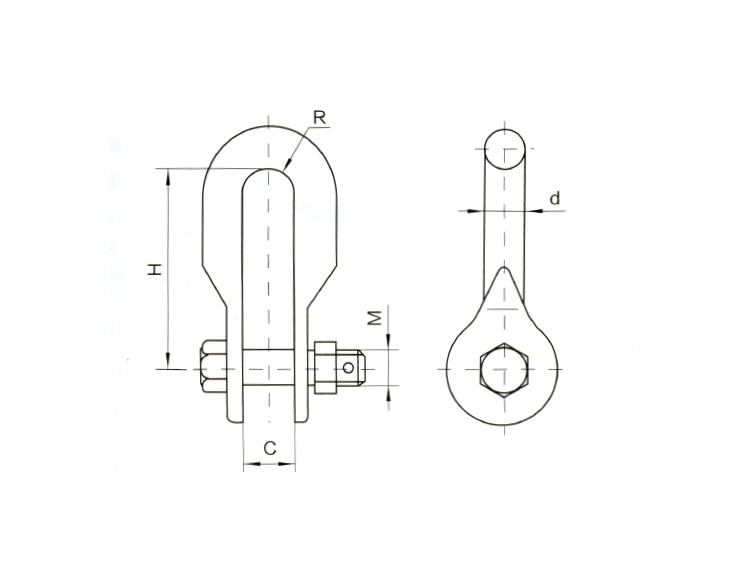

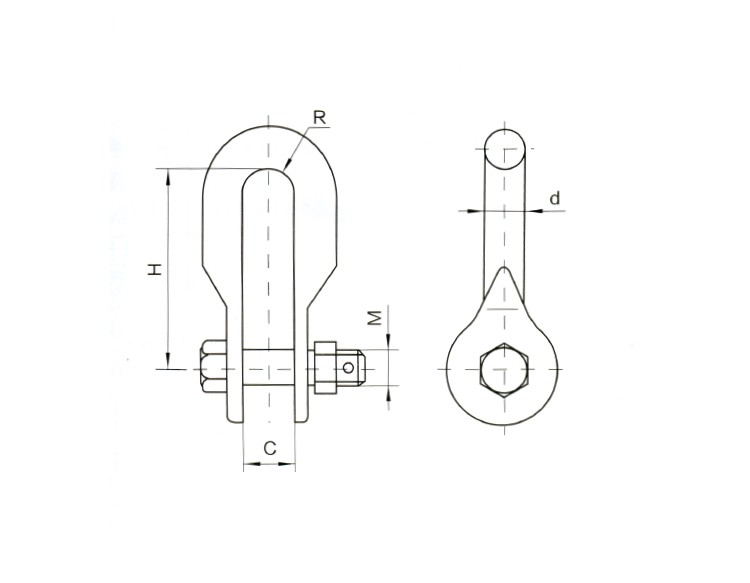

| Catalog No. | Dimensions(mm) | Failure Load(KN) | Weight(kg) | ||||||

| C | M | d | H | R | |||||

| UF-7 | 20 | 16 | 16 | 60 | 10 | 70 | 0.5 | ||

| UF-10 | 22 | 18 | 18 | 70 | 11 | 100 | 0.54 | ||

| UF-12 | 24 | 22 | 20 | 80 | 12 | 120 | 0.96 | ||

| UF-16 | 26 | 24 | 22 | 90 | 13 | 160 | 1.47 | ||

| UF-20 | 30 | 27 | 24 | 100 | 15 | 200 | 2.2 | ||

| UF-25 | 34 | 30 | 26 | 110 | 17 | 250 | 2.79 | ||

| UF-30 | 38 | 36 | 30 | 130 | 19 | 300 | 3.7 | ||

| UF-40 | 42 | 42 | 36 | 150 | 21 | 400 | 7 | ||

| UF-50 | 44 | 42 | 36 | 150 | 22 | 500 | 7 | ||

Here are some key points:

1.Types of Shackles:

1)D-Shackles (Chain Shackles): These have a D-shaped design and are ideal for straight-line pulling. They’re commonly used when the load is strictly vertical.

2)Bow Shackles (Anchor Shackles): Bow shackles have a rounder shape and can accommodate loads from multiple directions. They’re preferred when the lifting setup might shift or when the load exerts forces from various angles.

2.Material Selection:

1)Carbon Steel: Durable and strong, carbon steel shackles are suitable for general lifting purposes in non-harsh environments.

2)Alloy Steel: These shackles offer superior strength and toughness, making them ideal for heavy-duty lifting.

3)Stainless Steel: Best for corrosive environments (e.g., maritime applications), as they resist rust and corrosion.