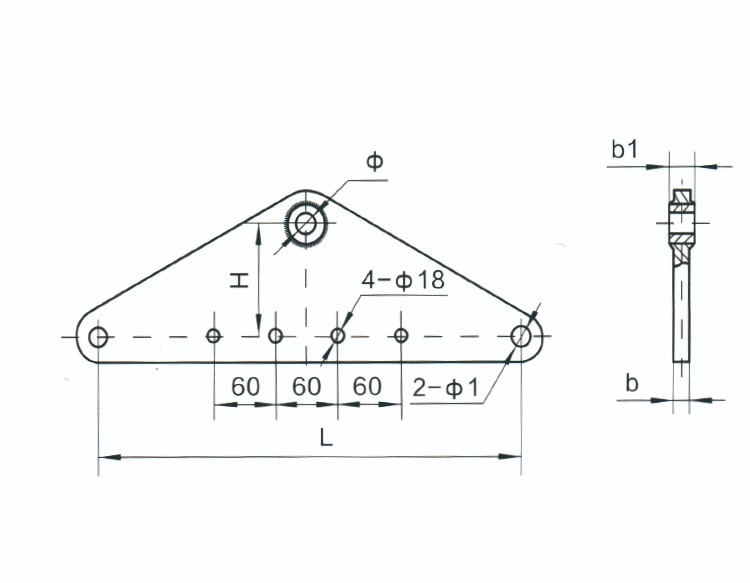

| Catalog No. | Dimensions(mm) | Failure Load(KN) | Weight(KG) | |||||||

| H | L | b1 | b | Φ | Φ1 | |||||

| L-3045 | 120 | 450 | 32 | 20 | 39 | 26 | 300 | 9.8 | ||

| L2-3045G | 110 | 450 | 32 | 22 | 39 | 26 | 300 | 10.5 | ||

| L-4050A | 130 | 450 | 38 | 26 | 39 | 30 | 400 | 16.9 | ||

| L-4250 | 160 | 500 | 38 | 26 | 45 | 30 | 420 | 18.1 | ||

| L-3245G | 200 | 450 | 32 | 20 | 39 | 26 | 320 | 18.6 | ||

| L-3250G | 130 | 500 | 32 | 18 | 33 | 26 | 320 | 9.8 | ||

| L-4255S | 200 | 550 | 32 | 18 | 39 | 26 | 420 | 8.4 | ||

| L-3260G | 130 | 600 | 28 | 20 | 33 | 26 | 320 | 8.9 | ||

| L-4250G | 200 | 500 | 28 | 18 | 33 | 26 | 420 | 15.33 | ||

| L-4260G | 130 | 600 | 32 | 20 | 39 | 26 | 420 | 11.4 | ||

| L-6450G | 145 | 500 | 36 | 28 | 45 | 33 | 640 | 17.1 | ||

| L-6460G | 145 | 600 | 36 | 28 | 45 | 33 | 640 | 29.52 | ||

| L-6470G | 250 | 700 | 36 | 28 | 45 | 33 | 640 | 33.24 | ||

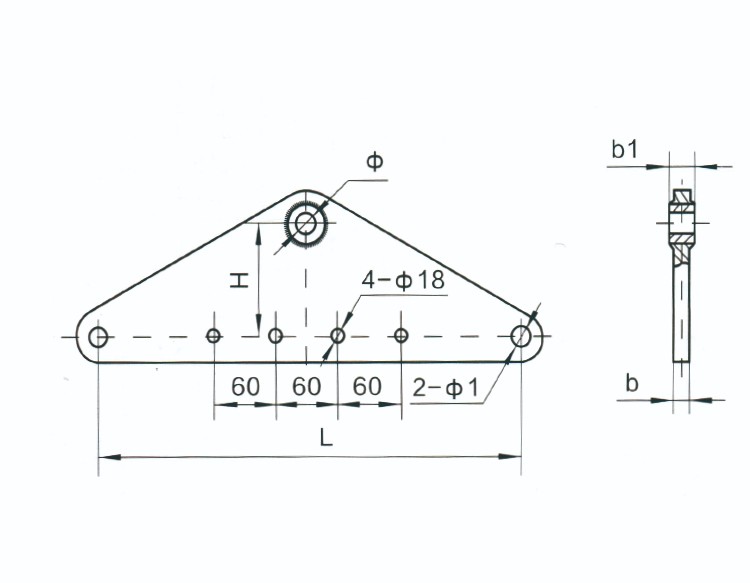

| Catalog No. | Dimensions(mm) | Failure Load(KN) | Weight(KG) | |||||||

| H | L | b1 | b | Φ | Φ1 | |||||

| L-21-110/400 | 110 | 400 | 20 | 16 | 26 | 20 | 210 | 6.5 | ||

| L-21-120/450 | 120 | 450 | 20 | 16 | 26 | 20 | 210 | 7.6 | ||

| L-21-120/500 | 120 | 500 | 20 | 16 | 26 | 20 | 210 | 9.3 | ||

| L-21-130/600 | 130 | 600 | 20 | 16 | 26 | 20 | 210 | 10.8 | ||

| L-25-110/400 | 110 | 400 | 24 | 16 | 30 | 24 | 250 | 7 | ||

| L-25-130/450 | 130 | 450 | 24 | 16 | 30 | 24 | 250 | 8.4 | ||

| L-25-130/500 | 130 | 500 | 24 | 16 | 30 | 24 | 250 | 9.1 | ||

| L-25-130/600 | 130 | 600 | 24 | 16 | 30 | 24 | 250 | 10.6 | ||

| L-32-130/400 | 130 | 400 | 28 | 18 | 33 | 26 | 320 | 9.1 | ||

| L-32-130/450 | 130 | 450 | 28 | 18 | 33 | 26 | 320 | 10 | ||

| L-32-130/500 | 130 | 500 | 28 | 18 | 33 | 26 | 320 | 11 | ||

| L-32-130/600 | 130 | 600 | 28 | 18 | 33 | 26 | 320 | 12.8 | ||

| L-42-140/400 | 140 | 400 | 32 | 20 | 39 | 26 | 420 | 10.2 | ||

| L-42-140/450 | 140 | 450 | 32 | 20 | 39 | 26 | 420 | 11.2 | ||

| L-42-150/500 | 150 | 500 | 32 | 20 | 39 | 26 | 420 | 12.6 | ||

| L-42-150/600 | 150 | 600 | 32 | 20 | 39 | 26 | 420 | 14.8 | ||

| L-21/25-110/400 | 110 | 400 | 24 | 16 | 30 | 24 | 250 | 7 | ||

| L-21/25-130/450 | 130 | 450 | 24 | 16 | 30 | 24 | 250 | 8.4 | ||

| L-21/25-130/500 | 130 | 500 | 24 | 16 | 30 | 24 | 250 | 9.1 | ||

| L-21/25-130/600 | 130 | 600 | 24 | 16 | 30 | 24 | 250 | 10.6 | ||

| L-21/32-130/400 | 130 | 400 | 28 | 18 | 33 | 20 | 320 | 8.4 | ||

| L-21/32-130/500 | 130 | 500 | 28 | 18 | 33 | 20 | 320 | 11 | ||

| L-21/32-130/600 | 130 | 600 | 28 | 18 | 33 | 20 | 320 | 12.8 | ||

Here are some details:

1.Material: They are typically made of ductile iron or steel.

2.Design: The standard triangular plate has 3 holes. However, triangular and rectangular plates are available with various hole spacing and thickness to suit either tension or suspension applications.

3.Applications: They are used in transmission lines to keep the distance of the bundled conductors at insulator strings and joint the eye-ended parts by compression lugs.