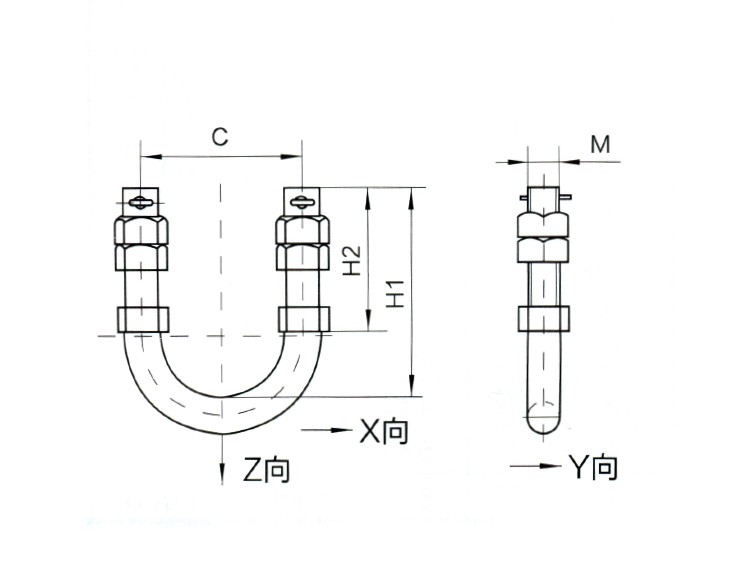

| Catalog No. | Dimensions(mm) | Failure Load(KN) | Weight(KG) | |||||||||

| C | M | H1 | H2 | X向 | Y向 | Z向 | ||||||

| U-1880 | 80 | 18 | 110 | 75 | 18 | 3.5 | 35 | 0.83 | ||||

| U-2080 | 80 | 20 | 120 | 80 | 24 | 4.9 | 47 | 1.08 | ||||

| U-2280 | 80 | 22 | 130 | 90 | 28 | 6.5 | 57 | 1.3 | ||||

1.Function and Applications:

1)U-bolts primarily serve as Rest+Guide+Hold down support for piping systems.

2)They can also be adapted to work as line stops with minor installation adjustments.

3)Common uses of U-bolts in piping solutions include:

(1)Providing lateral restraints to pipes.

(2)Supporting bare pipes smaller than 8 inches in diameter.

(3)Suppressing line vibrations by adding rigidity to the system.

(4)Supporting vertical elevated pipe runs.

(5)Preventing pipe movement and breakage during transportation.

2.Materials:

1)U-bolts can be manufactured from various strong and durable materials.

2)Widely used materials in the piping industry include:

(1)Plain Carbon Steel

(2)Stainless Steel

(3)Protective coatings (such as zinc plating, hot-dip galvanization, thermoplastic coating, and fluoropolymer coating) are added to prevent corrosion.

3.Types of U-Bolts:

1)Non-gripped U-bolt (U-bolt as Guide):

(1)Common and simple installation for pipe guiding.

(2)Does not restrict axial movement.

(3)Nuts are placed on the top and bottom of the support beam, leaving a gap between the pipe and the U-bolt surface.

2)Gripped U-bolt (U-bolt as Anchor):

(1)Functions as an anchor to stop pipe movement at the support location.

(2)Installed without space between the pipe and U-bolt.

(3)Both bolts are placed at the bottom of the secondary support structure and tightened against the pipe.