| Cataiog No. | Weight (kg) | Suitable Conductor | |||

| Steel cored aluminium stranded wire | aluminium wire | Galvanizeds teel strand | Aluminium CI steel wire | ||

| FDN-1/G | 1.7 | LGJ-35/6 | LJ-35 | GJ-35 | GLB-35 |

| FDN-2/G | 1.7 | LGJ-50/8 | LJ-50 | GJ-50 | GLB-50 |

| GJ-55 | GLB-55 | ||||

| LGJ-50/30 | LJ-70 | GJ-70 | GLB-70 | ||

| LGJ-70/10 | GJ-80 | GLB-80 | |||

| FDN-3/G | 2 | LGJ-70/40 | LJ-95 | GJ-95 GJ-100 | GLB-95 GLB-100 |

| LGJ-95/15 | |||||

| LGJ-95/20 | |||||

| FDN-1/2 | 2.5 | LGJ-95/55 | LJ-120 LJ-150 | GJ-120 GJ-150 | GLB-120 GLB-150 |

| LGJ-120/7 | |||||

| LGJ-120/20 | |||||

| LGJ-120/25 | |||||

| LGJ-150/8 | |||||

| FDN-2/3 | 3.4 | LGJ-120/70 | LJ-185 | GJ-185 | GLB-185 |

| LGJ-150/20 | |||||

| LGJ-150/25 | |||||

| LGJ-150/35 | |||||

| LGJ-185/10 | |||||

| FDN-3/4 | 4.2 | LGJ-185/25 | LJ-210 LJ-240 | ||

| LGJ-185/30 | |||||

| LGJ-185/45 | |||||

| LGJ-210/10 | |||||

| LGJ-210/25 | |||||

| LGJ-210/35 | LJ-300 | ||||

| LGJ-210/50 | |||||

| LGJ-240/30 | |||||

| LGJ-240/40 | |||||

| LGJ-240/55 | |||||

| FDN-4/5 | 5.1 | LGJ-300/15 | |||

| LGJ-300/20 | |||||

| LGJ-300/25 | |||||

| LGJ-300/40 | |||||

| LGJ-300/50 | |||||

| LGJ-300/70 | |||||

| LGJ-400/20 | LJ-400 | ||||

| LGJ-400/25 | |||||

| LGJ-400/35 | |||||

| LGJ-400/50 | |||||

| LGJ-400/65 | |||||

| FDN-4/6 | 5.4 | LGJ-400/95 | LJ-500 | ||

| LGJ-500/35 | |||||

| LGJ-500/45 | |||||

| LGJ-500/65 | |||||

| LGJ-630/45 | LJ-630 | ||||

| LGJ-630/55 | |||||

| LGJ-630/80 | |||||

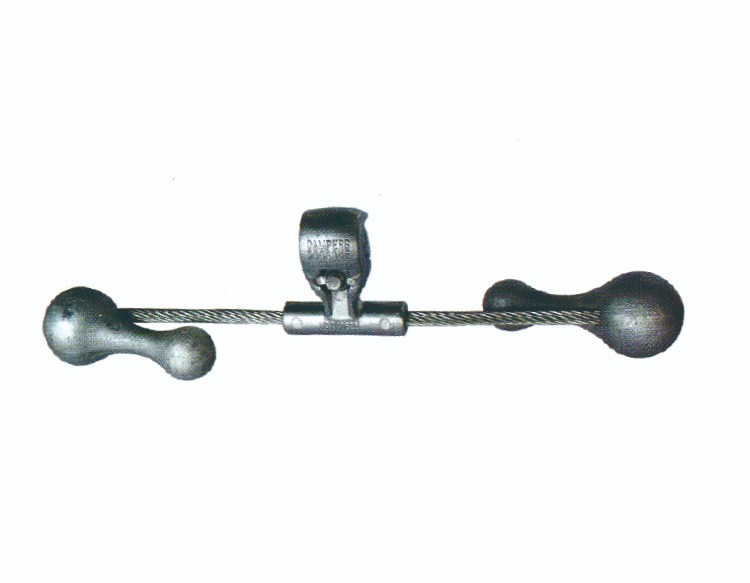

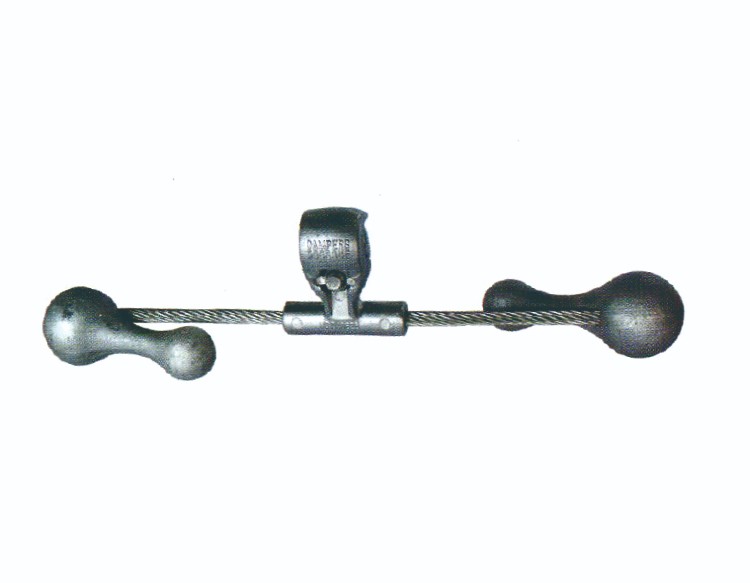

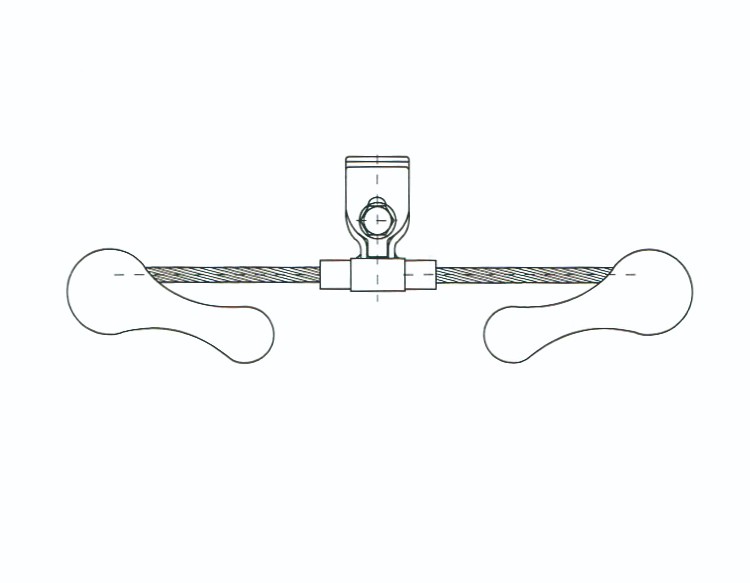

1.Structure:The structure of the anti-vibration hammer is usually divided into three parts: the hammer head, the steel strand, and the wire clamp. When the transmission line vibrates, the wire clamp vibrates with it, driving the vibration of the hammer head. This causes the steel strand to bend, absorbing the energy of vibration through the material energy loss of the steel strand and the friction between the wire strands.

2.Advantages:The FD-type anti-vibration hammer, with its parameter optimization, has an inherent frequency nearly identical to the desired value and has better anti-vibration performance for specific working conditions. The model has nine important parameters supporting the modelling, with the center of the wire clamp as the axis of symmetry.

3.Application:This device is particularly useful in regions where transmission lines are subject to wind-induced vibrations, which can cause damage to fixtures, broken strands of the wire, and even broken wires. The anti-vibration hammer has proven its good suppression effect on breeze vibration over decades of operating experience.