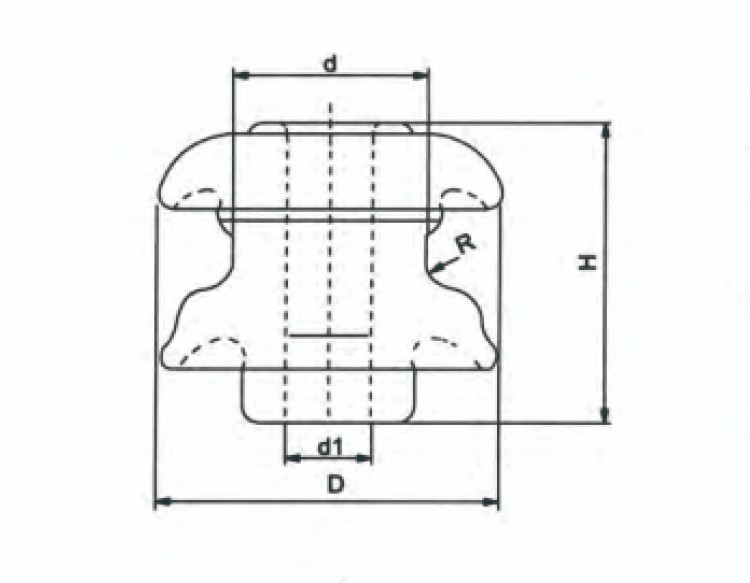

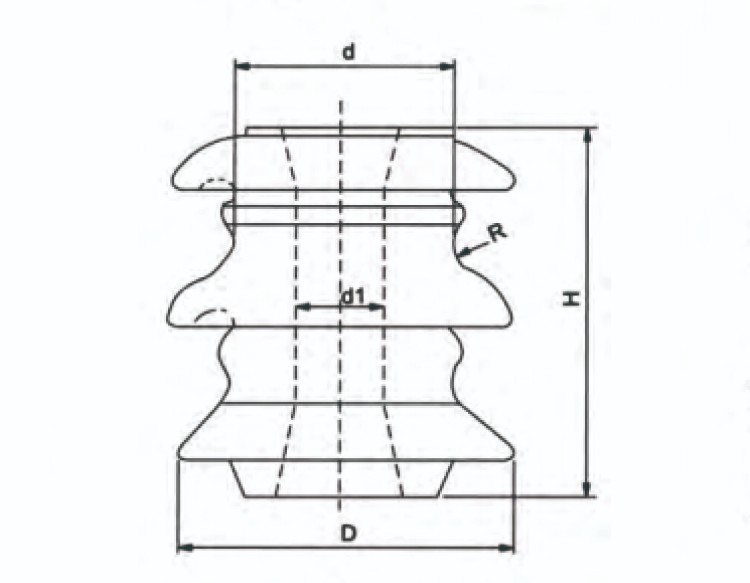

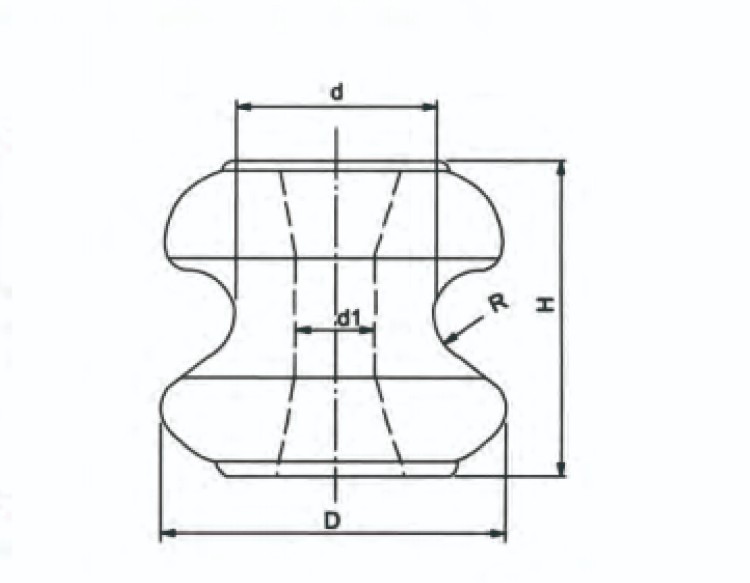

| Fig No. | 2 | 1 | 1 | 3 | 3 | 3 | |||

| CLASS ANSI | ED-2 ( C ) | ED-2 (B ) | ED-2 (B )1 | 1617 | 1618-1 | 1618-2 | |||

| Main Dimansions ( mm ) | H | 80 | 76 | 76 | 65 | 75 | 75 | ||

| D | 80 | 89 | 89 | 76 | 89 | 89 | |||

| d | 50 | 48 | 48 | 46 | 55 | 55 | |||

| d1 | 22 | 21 | 17.5 | 17.6 | 17 | 17 | |||

| R | 6 | 10 | 10 | 9 | 12.5 | 12.5 | |||

| Mechanical Failing Load ( KN ) | 13 | 12 | 12 | 9 | 10 | 13 | |||

| Minimum Flashover Voltage | Power Frequency | Dry ( kv ) | 25 | 25 | 25 | 20 | 20 | 25 | |

| Wet ( kv ) | 15 | 12 | 12 | 9 | 9 | 12 | |||

| Weight ( kg ) | 0.5 | 0.5 | 0.5 | 0.4 | |||||

Here are some details about these insulators:

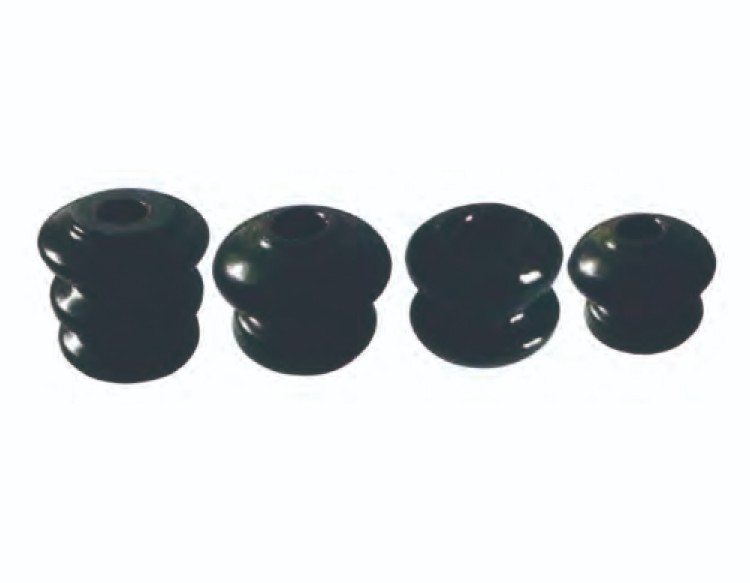

1.Insulator Type: These insulators are also known as spool insulators or butterfly insulators.

2.Usage: They are used at the end of distribution lines or at sharp turns where there is excessive tensile load on the lines. These insulators can be mounted either in the vertical or horizontal position.

3.Material: They are typically made of porcelain.

4.Interchangeability: The connecting fittings of these insulators are required to be interchangeable.

5.Testing: Various electrical, mechanical, physical and environmental condition change tests are conducted on these insulators according to different models and service conditions.