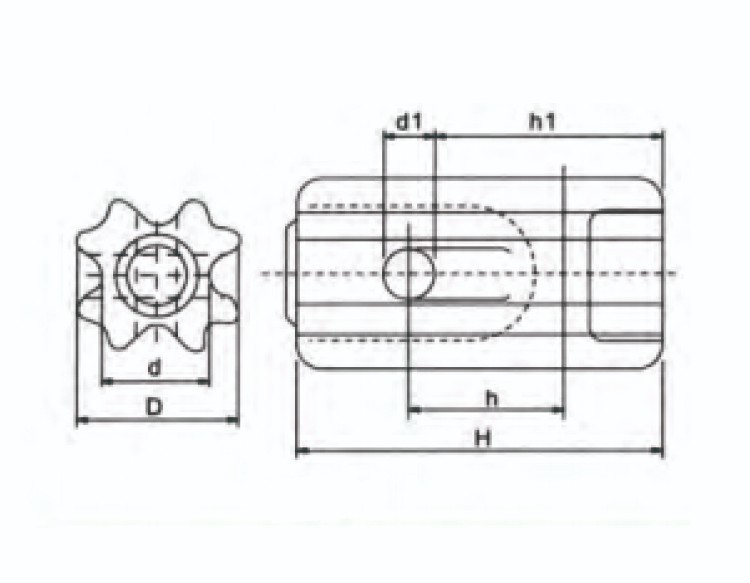

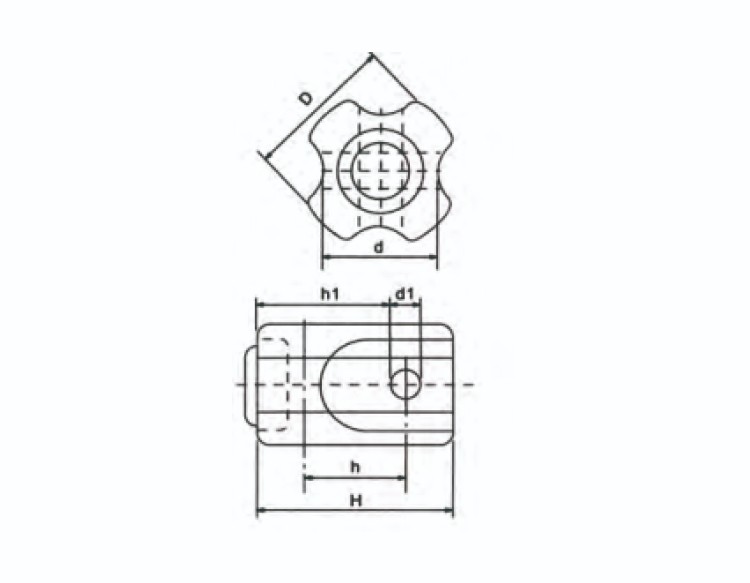

| Fig No | 2 | 2 | 2 | 1 | ||

| CLASS ANSI | 54-1 | 54-2 | 54-3 | 54-4 | ||

| Main Dimansions in( mm) | H | 89 | 108 | 140 | 171 | |

| h | 44 | 57 | 67 | 79 | ||

| h1 | 64 | 76 | 103 | 114 | ||

| D | 64 | 73 | 86 | 89 | ||

| d | 44 | 54 | 60 | 60 | ||

| d1 | 16 | 22 | 25 | 25 | ||

| Mechanical Failing Load ( KN ) | 44 | 53 | 89 | 89 | ||

| Leakage Distance ( mm ) | 41 | 47 | 57 | 76 | ||

| Flashover Voltage | Power Frequency | Dry (KV) | 25 | 30 | 35 | 40 |

| Wet (KV) | 12 | 15 | 18 | 23 | ||

| Weight (Kg) | 0.5 | 0.65 | 1.2 | 2.2 | ||

These insulators are part of a broader category that includes pin, post, dead-end, and strain type insulators used for distribution lines. They are essential for the construction and maintenance of electric distribution systems.

In terms of material, some ANSI strain insulators are made of a fiberglass-reinforced resin rod core, polymer material weathersheds, and metal end fittings. These are intended for use on overhead transmission lines for electric power systems, particularly those operating at 70 kV and above.

It’s important to note that when replacing porcelain or glass insulators with non-porcelain insulators, all phases for line conductors, or for dead-end insulators, should be replaced. Also, care should be taken not to overtighten polyethylene insulators as excessive tightening can damage the neck of the insulator, leading to failure.