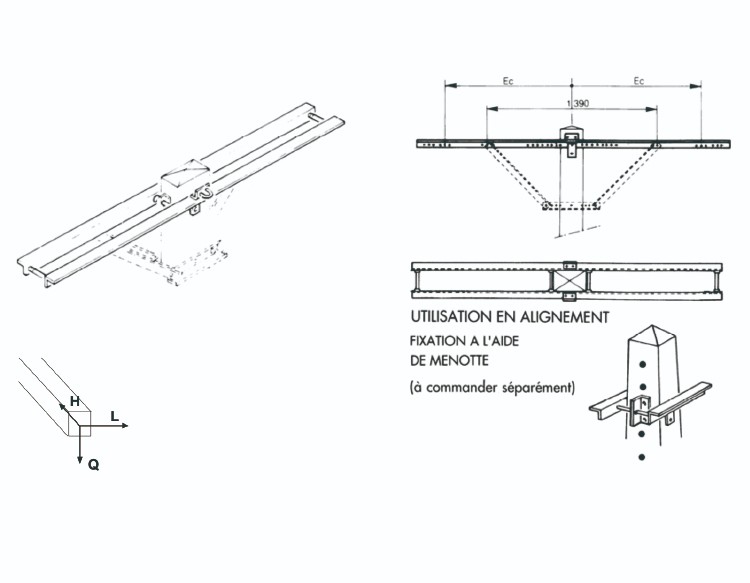

| Référence traverses | Profilé | Ec | Effort nominal * (daN) | Poids avec ridoir (kg) | ||

| Q | L | Q contrefiché | ||||

| TAD 1050 60 | L60x6 | 1050 | 125 | 290 | 390 | 37 |

| TAD 1200 60 | L60x6 | 1200 | 110 | 250 | 250 | 37 |

| TAD 1500 60 | L60x6 | 1500 | 90 | 180 | 160 | 45 |

| TAD 1050 70 | L70x7 | 1050 | 210 | 460 | 560 | 43 |

| TAD 1200 70 | L70x7 | 1200 | 190 | 400 | 425 | 43 |

| TAD 1500 70 | L70x7 | 1500 | 140 | 340 | 250 | 53 |

| TAD 1200 80 | L80x8 | 1200 | 275 | 530 | 500 | 60 |

| TAD 1500 80 | L80x8 | 1500 | 225 | 470 | 410 | 70 |

| TAD 1700 80 | L80x8 | 1700 | 190 | 375 | 310 | 80 |

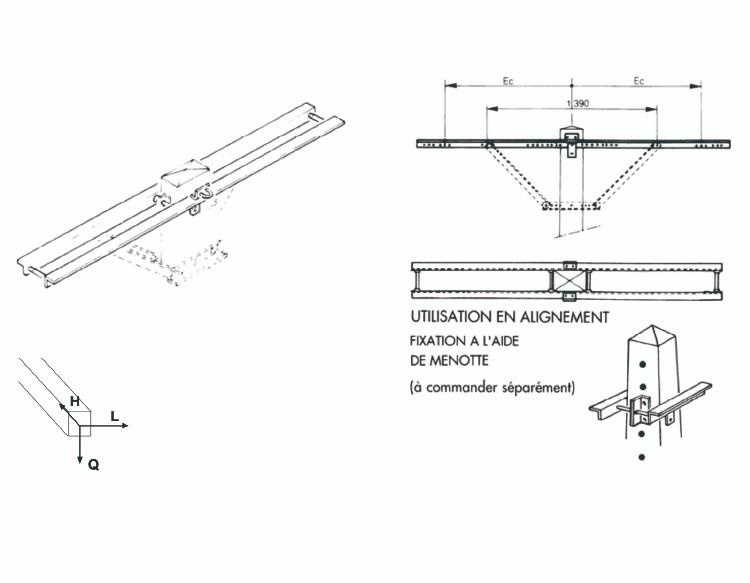

| Référence | Composition | Utilisation | Poids (kg) |

| CFS | 1 CF+1ECF+ 1 BH14.40 | H61 (TAS) | 4.2 |

| 2 fois CFS | 1 CF+ 1 ECF+1 BH14.40 | TAD | 8.4 |

| CFD | 1CF+1ECF+ 1 BH14.40 | H61 (TAS) | 6 |

| 2 fois CFD | 1CF+1 ECF + 1BH14.40 | TAD | 12 |

Here are some details about this component:

1.Structure: The crossbar maintains the cable suspended via the armament. The neutral carrier is pinched in an alignment clamp and then anchored in an anchoring clamp. These clamps are respectively suspended from alignment and anchoring consoles.

2.Usage: It is part of the overhead electrical network built from cables, supports, and armaments.

3.Components: The crossbar is associated with devices to controlled elongation “OMEGA”, which provide a considerable additional guarantee against exceptional overloads in simple and double stop.

4.Installation: The mounting of the KAPPA crossbars on metal supports must be done using an SGM plate. The metal supports must be provided with an SGM plate, welded at the height of the crossbar fixing.